Business

- TOP

- Business

About Us

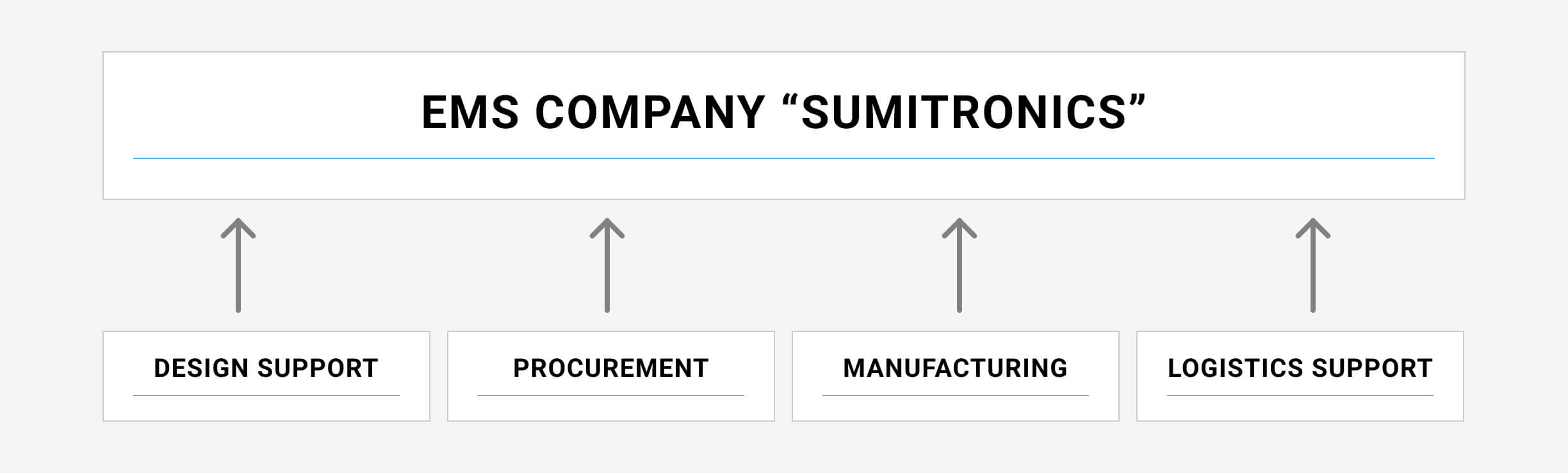

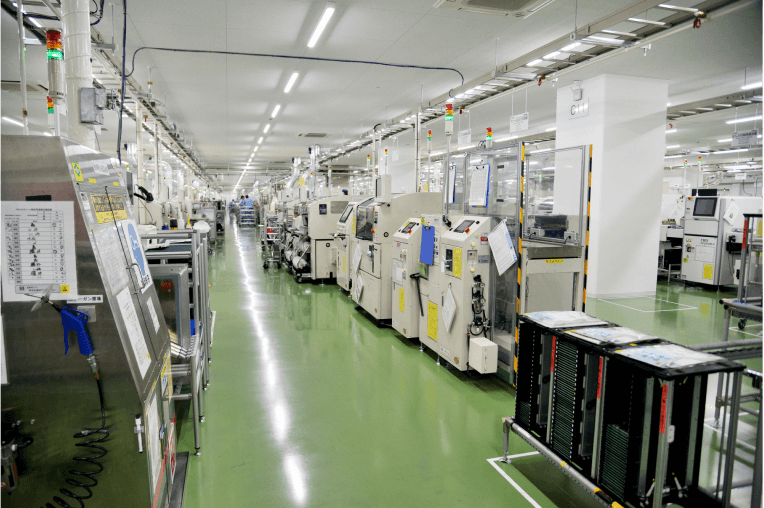

We Are an Electronics Manufacturing Service Company

We have established a supply chain management (SCM) system using its own network and systems across Asia, North America, and Europe, etc., and has been providing its EMS business internationally by utilizing the corporate strength of the Sumitomo Corporation group, which has a global reach.

Our primary advantage is the ability to provide an efficient and high quality service by making full use of the experience accumulated through the creation of our self-developed system. We can combine a variety of services matched to the customer’s request, respond quickly and appropriately, and can provide solid support to our customers’ businesses based on our own expertise.

Our Strength

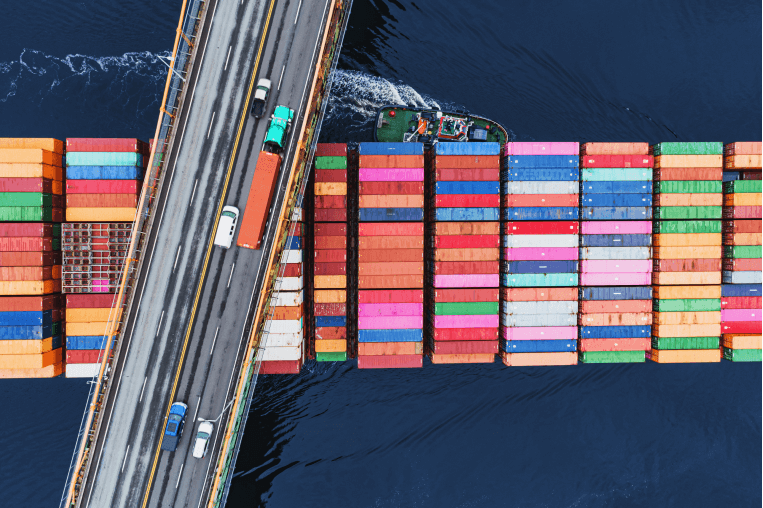

Global Support

Smooth operation including overall optimization, international component procurement (integrated negotiations), outstanding stock flexibility between sites, and relocation of production sites based on a global network centered on Asia, but also extending to Europe and America.

Material Procurement

We have been dealing with over 1,000 material manufacturers and trading companies, and procurement within and outside the group. We will reduce cost by Value Analysis (VA) and Value Engineering (VE) proposals for alternative local components. We realize our customers’ production line make running without suspension by appropriate order control operation and inventory management with our credit capability.

Cost Reduction

We facilitate continuous cost reduction by:

- Harnessing benefits of bulk purchasing of electronic components.

- Adopting proved alternatives for Japanese PCB assemble manufacturers as well.

- Cutting implementation costs by adopting the optimal mounting destination to our customer.

BCP Development

We have established an internal system to minimize supply issues, such as delays of materials delivery from unexpected disasters. We monior the status of the supply chain and identify potential risks, and make full use of our network to minimize the impact on our customers’ production.

Production Control for Multiple Sites

With our centralized management for the manufacturing schedule of multiple sites, we manage to realize the minimized inventory volume in each site and JIT delivery to your production line.

Improve Balance Sheet and Cash Flow

With us, our customer will be enable to:

- Minimize financial burden by reducing inventory through just-in-time (JIT) delivery per PCB.

- Reduce investment costs for new manufacturing equipment with our strength.

Global JIT Delivery

We can provide our customer:

- Logistics costs reduction by using shared delivery through our network.

- Globally standardized JIT delivery services.

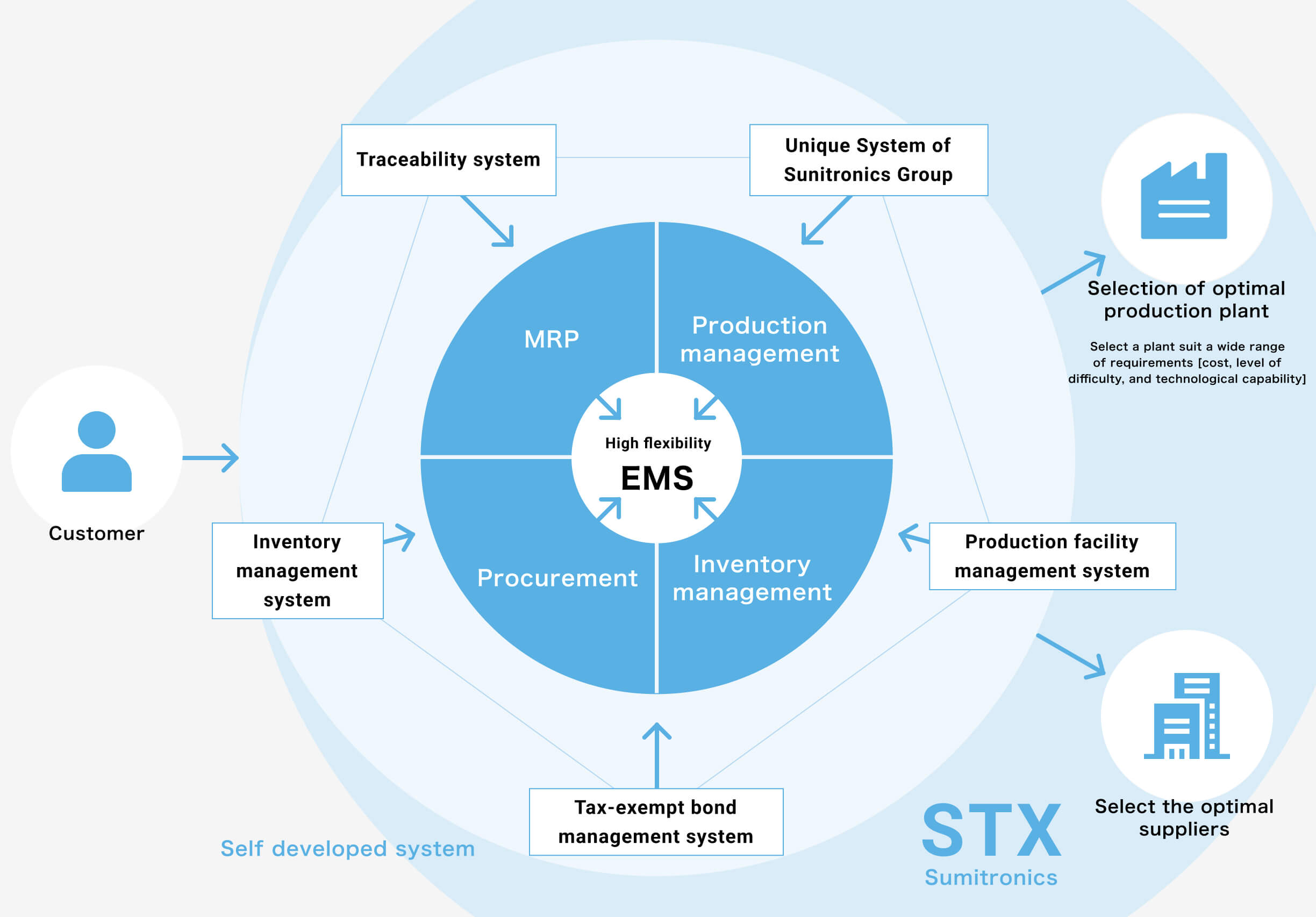

Self Developed System

Implemented Cutting-edge of Self Developed System

Our own unique self-developed system which integrates the know-how accumulated through our EMS business allows us to consolidate management of design/development, procurement, logistics, and manufacturing. This system enables us to respond flexibly to our customers’ needs as well as actively pursue such things as introducing EDI to our parts suppliers and collaborating with the production management systems of our manufacturing partners.

We have also developed a traceability system which is vital for product quality assurance. As such, we are capable of consistent management from procurement to manufacturing.

By utilizing the web, we also provide real-time information on various EDIs and inventory statuses to our customers and suppliers.